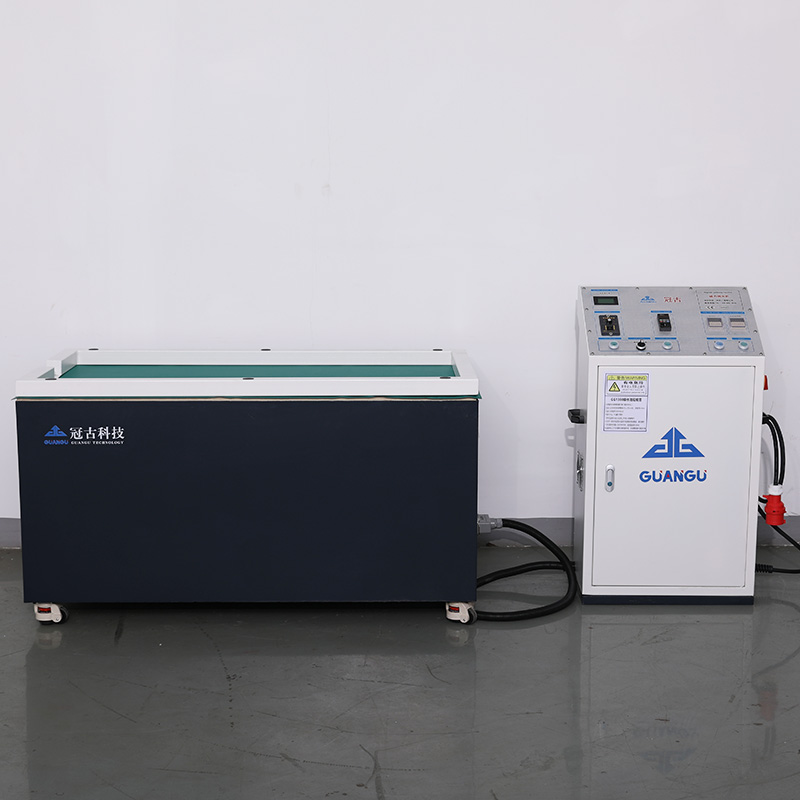

RotterdamDUAL STATION TRANSLATIONAL MAGNETIC ABRASIVE POLISHING MACHINE GG1980Method

The company mainly produces: magnetic polishing machine, magnetic grinding machine, magnetic deburring machine, magnetic tumbling machine and other polishing machine equipment. Applicable to copper parts, aluminum parts, stainless steel parts, alloy parts and other types of metal parts of the surface treatment problems. One-time solution to polishing cleaning deburring and other post-processing problems. Remove the batch front, oil, welding spots, oxide layer, knife pattern, etc., no dead end bore, cross hole polishing and cleaning, does not affect the accuracy, do not hurt the workpiece.

Video

Hotline

400-800-3945

| Product Model | GG1980 |

| Dimensions | 1980*720*1088 |

| Grinding groove size | 1800*520(drum) |

| Power supply | AC380v(50 60Hz)16A |

| Motor power | 4KW*2 |

| Equipment weight | 580KG

|

| Grinding capacity | 40-60Kg |

| Operation mode | forward, reverse, and translation |

| Steel needle | 12kg |

| Lapping liquid | 100L |

| Motor speed | 1400 RPM |

| Diameter | 0.2-2.00mm |

Magnetic polishing machine can be used for surface treatment of various materials, such as metal, plastic, ceramics, glass, etc. It is especially suitable for complex shapes and easily deformed workpieces. Magnetic polishing machine has the following advantages:

Improve surface finish and achieve mirror effect.

Remove surface scratches and defects.

Remove burrs and chamfers.

Increase surface gloss.

Improve the fit and wear resistance of parts.

In short, magnetic polishing machine is a highly efficient surface treatment equipment that can improve the surface properties of materials and enhance their aesthetics and usability.

1. Precision metal stamping parts

2. Stainless steel parts, 304 stainless steel screws and nuts

3. Magnesium aluminum die casting

4. Zinc aluminum die casting

5. Precision spring, shrapnel parts

6. Electronic, computer and communication parts

7. Walking heart, walking knife, CNC automatic lathe parts

8. Aerospace parts, medical equipment parts